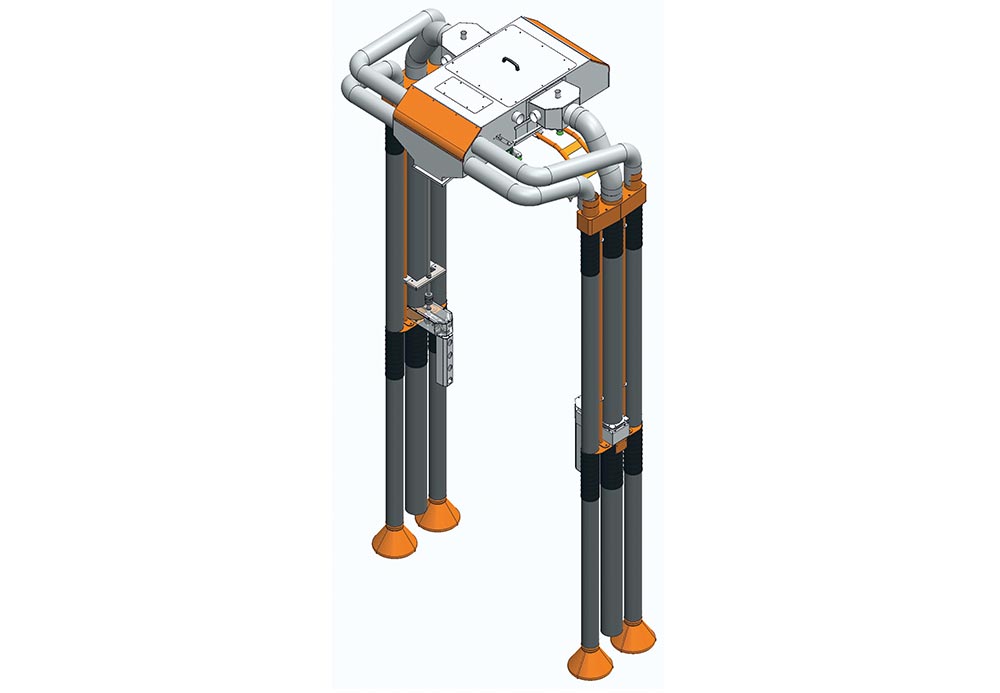

LPT GLI-CLEAN is suitable for both individual machines as well as series configurations. This superior product ensures frequent gliding and cleaning with effective blowing and suction systems to ensure your machines are always clean – and negates the need to stop the production line to allow manual cleaning.

GLI-CLEAN communicates with an Auto Doffing machine through non-contact free sensors and travels to a parking position before doffing begins.

GLI-CLEAN controls the waste from the drafting system through a cleaning nozzle. The travelling units serve a group of machines and whenever one machine stops due to slubbing or maintenance, the fan motor stops immediately. The drive motor ensures the travelling unit reaches a parking position. Once the machine resumes, the fan motor is re-activated for the cleaning.

GLI-CLEAN is technically sturdy, robust and packed with special features.

Salient Features

- Stable Twin Track system with specially treated steel

- Standard 3 phase motor with 1.5 kw / 2.2 kw capacity

- Splash lubricated Gear unit.

- Option modules Programmable Logic Control system.

- Easily washable & detachable type micro filter screen.

- Primary current supply through enclosed safety contact rail.

- Non-contact reversal system.

- Designed to suit – BTS, Link coner, Auto coner & Compact spinning systems.

- Suitable for straight and curved track system.

- Uniform blowing and suction provided at Flyer side of the Speed Frame.

- Single blowing and single suction hoses up to the floor level.

- Nozzles can be provided in sliver side for ceiling and sliver cleaning

- Special blowing attachment for different model Speed Frames.

Optional Features

- Centralized waste collection and disposal system

- Swivel arrangement of the suction nozzle to clean the drafting area.

- Optic obstacle sensor control systems

- Auto parking system

- Warve cleaning system

LPT GLI-CLEAN Belt Drive Model

This model has a lightweight chamber as the fan motor is designed to be

stationary at the track end. The light-weight chamber delivers superior efficiency including:

- Higher blowing and suction performance

- Less maintenance

- Machine’s maximum length covered

- Suitable for self-discharge system

- Less power consumption

LPT GLI-CLEAN Weaving Model

This model has been designed with in-depth experience, trials and R&D for an almost-perfect system for weaving mills. Yarn and Warp are increasingly stressed with significantly higher running speeds. This leads to a considerable increase in abrasion and a dramatic accumulation of dust and fly in the weaving shed. Our product, equipped with fan motors of 4 kW of installed performance, and a superior nozzle deficiency, has the ability to reach what may be described as inaccessible places.

The advantages are

- Decreasing thread breakage

- Less accumulation of fly on the fabrics

- Increase in productivity due to less maintenance

- Lower expenditure for repairs and maintenance.

- Large surface fine filters ensure a constant efficiency

- Flexible nozzle arrangement

Salient Features

- No direct electrical supply to the cleaner and fan stop.

- Automatic clockout of Spinning and Cone winding in Link systems.

- Standard 3 phase motor with 1.5 kw capacity

- Park command activated by the Limit switch control.

- Simple modular construction

- Lower power consumption and easy maintenance.

Technical Specifications

PARAMETERS |

GLI-CLEAN B2 |

GLI-CLEAN P3 |

GLI-CLEAN P4 |

|---|---|---|---|

| Fan Motor, kW | 1.5, 3F, 415 V | 2.2, 3F, 415 V | 4, 3F, 415 V |

| Drive Motor, kW | – | 0.15, 3F, 415 V | 0.15, 3F, 415 V |

| Traveling Speed, m/min | 12 | 8/12/16 | 12/16 |

| Air Volume, m 3 / hr | 2350 | 2550 | 3350 |

| Suction Pressure, mm Wg | 220 | 240 | 300 |

| Suction Hoses, Nos. | 4 x Ø100 mm | 4 x Ø100 mm | 4 x Ø100 mm |

| Blowing Hoses, Nos. | 2 x Ø125 mm | 2 x Ø125 mm | 16 x Ø75 mm |

| Filter Area, m 2 | 0.22 | 0.15 | 0.15 |

| No. of push button controls | – | 3 | 3 |

| Nozzles, mm | Ø8 – Ø35 | Ø10 – Ø30 | Ø75 |

| No. of Nozzles, Nos. | 8 – 16 | 10-16 | 12-16 |

| Stopping, Discharging & Reverse operation | Mechanical control | Mechanical/Electronic controlled | |

| Traveling Path | Straight line | Straight line / Curved / Circular | |

| Waste collection | Manual/CWCS | ||

| Blowing attachments | Adjustable | ||

Enquire about any product available now or for any matter regarding Sales, Installation or Service.

If interested to know more you can click here,

Enquire Now (or) Spinning Brochure(or) Weaving Brochure