LAKSHMI PRECISION TECHNOLOGIES LIMITED, INDIA & SAMYOUNG PLANT CO., LTD, SOUTH KOREA

A Complete Crushing Solution

Overview

LPT partners with Samyoung Plant Co., Ltd., a global crusher technology leader. This milestone blends LPT’s engineering with Samyoung’s innovation. Together, they aim to deliver advanced solutions for India’s growing market.

Quality

LPT, certified with ISO 9001, 14001, and 45001, is known for precision manufacturing. Samyoung Plant, with 40+ years of expertise, leads South Korea’s crusher market with durable, sustainable technology.

Our Products

Jaw Crushers

Features

- Welded Frame Construction

- Easy Wedge adjustment systems for controlling CSS settings

- Reliable high crushing rate & User Friendly

- Shorten the setting time with hydraulic outlet clearance controller

- Improve Durability by analysing the frame structure & stress

- Improve by 20% compared to jaw crushers of the same class

- Increase inlet size: About 5%

- Increase number of rotations: About 10%

Improve Maintainability & Durability

- Shorten the setting time with the hydraulic outlet clearance controller: 10 minutes or less

- Improve durability by analyzing the frame structure & stress

| Model | Input Size (mm) |

Output (t/h) Setting Clearance (mm) |

RPM | Motor (kw) |

Weight (ton) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 60 | 80 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 300 | |||||

| LFSK-2514 | 640 × 345 | 42 | 53 | 76 | 250 | 37 | 4.1 | ||||||||

| LFSK-3020 | 750 × 500 | 42 | 53 | 72 | 94 | 117 | 138 | 250 | 45 | 7.7 | |||||

| LFSK-3624 | 900 × 600 | 108 | 132 | 164 | 186 | 196 | 250 | 75 | 12.2 | ||||||

| LFSK-4430 | 1,100 × 750 | 200 | 250 | 290 | 325 | 360 | 250 | 110 | 22 | ||||||

| LFSK-5040 | 1,250 × 1,000 | 313 | 363 | 413 | 464 | 482 | 500 | 220 | 220 | 41 | |||||

| LFSK-6048 | 1,500 × 1,200 | 425 | 468 | 510 | 550 | 590 | 640 | 190 | 300 | 69.7 | |||||

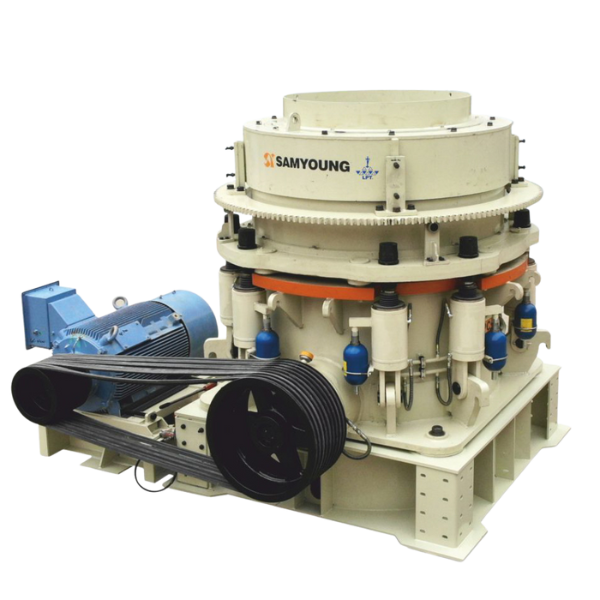

MC Cone Crusher

Improve Maintainability & Durability

- Shorten the liner replacement time by changing… 2 hours (MC cone)

- Primary and secondary cones inter-compatible with liner replacement

- Spiral gears reduce vibration & boost efficiency

- Improve by 20% compared to Cone crushers

- Increase inlet size: About 20%

- Increase number of rotations: About 10%

| Model | Input Size(mm) | Output (t/h) Setting Clearance (mm) |

RPM | Motor (kw) |

Weight (ton) |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Closed (mm) |

Open (mm) |

4 | 6 | 10 | 13 | 16 | 20 | 25 | 30 | 40 | 50 | 60 | ||||

| LMC-100(A) /CC-900 |

125 | 140 | 45 | 50 | 70 | 80 | 90 | 105 | 630 | 37~55 | 12 | |||||

| LMC-100(B) /CSH-900 |

50 | 70 | 27 | 48 | 57 | 65 | 80 | 630 | 37~55 | 12 | ||||||

| LMC-150(A) /CC-1200 |

170 | 190 | 72 | 90 | 110 | 135 | 155 | 185 | 200 | 530 | 75~110 | 24 | ||||

| LMC-150(B) /CSH-1200 |

70 | 100 | 70 | 90 | 110 | 135 | 530 | 75~110 | 24 | |||||||

| LMC-200(A) | 210 | 235 | 125 | 150 | 185 | 210 | 250 | 265 | 580 | 160 | 23 | |||||

| LMC-200(B) | 90 | 120 | 95 | 125 | 150 | 185 | 580 | 160 | 23 | |||||||

| LMC-300(A) | 270 | 305 | 220 | 290 | 335 | 390 | 455 | 550 | 220 | 43 | ||||||

| LMC-300(B) | 135 | 175 | 145 | 185 | 220 | 260 | 290 | 550 | 220 | 43 | ||||||

| CC-2100 | 300 | 335 | 360 | 430 | 560 | 700 | 800 | 435 | 200~300 | 79 | ||||||

Vertical Impact Crushers

Features

- Better Quality product shape

- free flow rotor arrangement

- rock and rock crushing system for low near cost

- high tensile strength steel welded frame constructing for better reliability

- produces the better cubical shape of product

- better efficiency in sand production

Increased Convenience and Durable

- Easy internal consumable checks & replacements

- Maintain optimal conditions with CASE CADE & OVER FLOW TYPE

- Low noise, low vibration with solid frame

Increased Production of First Grade Aggregate & Crushed Sand

- Crushing through rotor rotation

- Granularity improved via rock-to-rock method

- High‑quality SMA & primary aggregates

- Increased crushed sand output

| Contents | Production | |||

|---|---|---|---|---|

| Dead Stock | LSY-9000V | Production | Capacity (t/h) | LSY-9000V |

| Rotor (mm) | 900 | Operation Type | Dual | |

| Rotor Speed (m/sec) | 45 ~ 65 | Motor (kw) | 190×2 | 220×2 |

| Rotation Speed (rpm) | 1000 ~ 1800 | Sand Production | 265 ~ 630 | 310 ~ 730 |

| Drive Type | V-BELT | Shaping | 265 ~ 630 | 310 ~ 730 |

| Max. input size (mm) | 25 × 55 × 70 | |||

| Purpose | Shaping | Sand Making | |||

| 1. The above capability is applied in case the aggregates, as a specific gravity of 1.6, are supplied consistently. | ||||

Vibrating Feeder

Features

- High qulaity near resistant plates circuits

- flexible operation with long life of parts

- feeders are compatible with wide range of crushing equipment

Increased Convenience and Durability

- Smooth driving and controlled flow of raw materials

- Powerful counterweight vibration device ensures constant and strong vibration movement

| TECHNICAL SPECIFICATIONS | ||||

|---|---|---|---|---|

| Model No. | Width × Length (mm) | Production (t/h) | Motor (kw) | Motor Type |

| LQH-7530 | 750 × 3,000 | 80~100 | 11 | Horizontal |

| LQH-9036 | 900 × 3,600 | 100~200 | 15 | Horizontal |

| LQH-1042 | 1,050 × 4,200 | 200~300 | 30 | Horizontal |

| LQH-1248 | 1,200 × 4,800 | 300~400 | 37 | Horizontal |

| LQH-1854 | 1,800 × 5,400 | 500~600 | 55 | Horizontal |

Vibrating Screen

Features

- Made as a compact and duraablescreen with scalping sizing & capabilities

- incerpereption of hulkbolt systemfor better reliability and easy maintanance

- moduler design of it screen for easy replacement and inteterchargability

- Anti vibration media for better circular motion for segregation, sepration & satisfication

Increased Convenience and Durability

- Not sensitive to low or high loads, provide sorting efficiency constantly

- Can be operated smoothly with very simple structure

- Generate a constant effect on each screen with strong vibration

| Model | Section | W x L (mm) | Motor (kw) |

|---|---|---|---|

| LOP-1236 | 1 ~ 4 | 1,200 x 3,600 | 11 |

| LOP-1536 | 1 ~ 4 | 1,500 x 3,600 | 15 |

| LOP-1842 | 1 ~ 4 | 1,800 x 4,200 | 22 |

| LOP-2160 | 1 ~ 4 | 2,100 x 6,000 | 37 |

| LOP-2460 | 1 ~ 3 | 2,400 x 6,000 | 45 |

| LOP-2470 | 1 ~ 3 | 2,400 x 7,000 | 30 x 2 |

| LOP-2780 | 1 ~ 3 | 2,700 x 8,000 | 37 x 2 |

| LOP-3090 | 1 ~ 3 | 3,000 x 9,000 | 45 x 2 |

Crushed Sand production

Sand Unit & Dewatering Screen

- Excellent classification efficiency

- Easy to install in narrow spaces

- Excellent dehydration efficiency

- Polyurethane mesh is used and can be partially replaced when worn.

- Powerful vibration generation and amplitude control are also possible.

| Model | Pump | Cyclone Type |

Dewatering Screen | Water Tank (M3) ton |

|||

|---|---|---|---|---|---|---|---|

| Size | kw | Type | Area | kw | |||

| LSYSU 300 x 100 | 6" | 37 | 650 | 10 x 24 | 2.5 | 2.2 x 2 | 6 |

| LSYSU 500 x 160 | 8" | 45 | 900 | 15 x 30 | 4.5 | 22 | 10 |

| LSYSU 600 x 200 | 10" | 55 | 900 | 18 x 33 | 6 | 22 | 18 |

| LSYSU 800 x 300 | 12" | 90 | 1100 | 21 x 45 | 9.5 | 22 | 25 |

| LSYSU 800 x 400 | 12" | 90 | 1100 | 21 x 54 | 11.3 | 30 | 30 |

| LSYSU 1000 x 500 | 12" | 90 | 1100 | 24 x 60 | 14.4 | 37 | 50 |

Discover our full range of high-performance products, complete with specifications, use cases, and technical details. Download the brochure to learn more.

Enquire for

FREE TECHNICAL CONSULTATION

From machinery to maintenance, we provide expert guidance to boost efficiency.