Transforming Waste into Value

Our Recycling Process

Lakshmi Precision Technologies Limited (LPT) is an ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, and 5S Excellence Certified Company, established in 1983. Headquartered in Coimbatore, India—a hub for textile machinery and manufacturing—LPT has built a strong reputation for precision engineering.

Our New Initiative

Expanding into sustainable innovations, LPT is now manufacturing advanced recycling machines. These solutions are designed to optimize waste management, improve resource efficiency, and promote environmental sustainability.

Our Products

APPLICATIONS

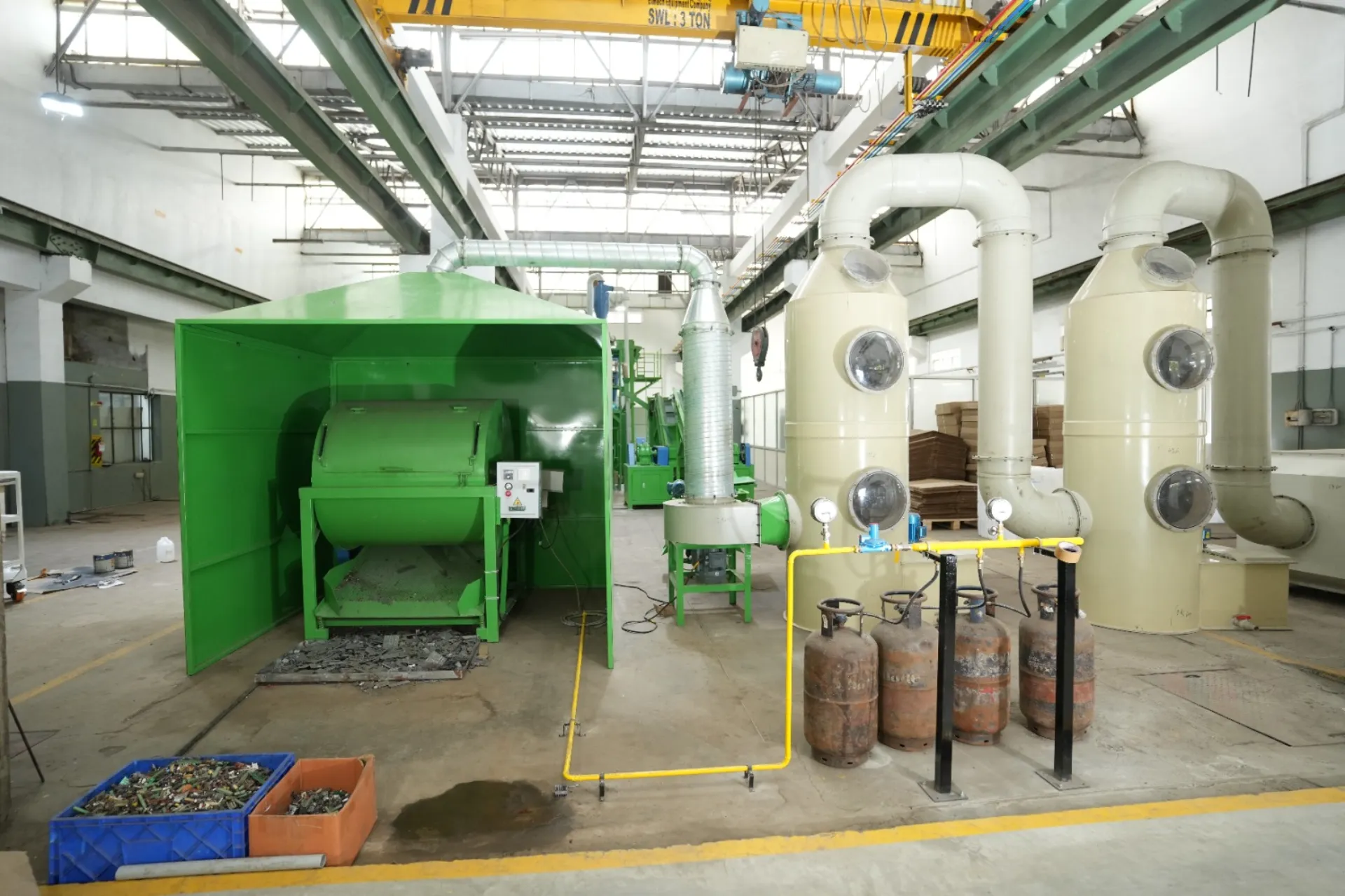

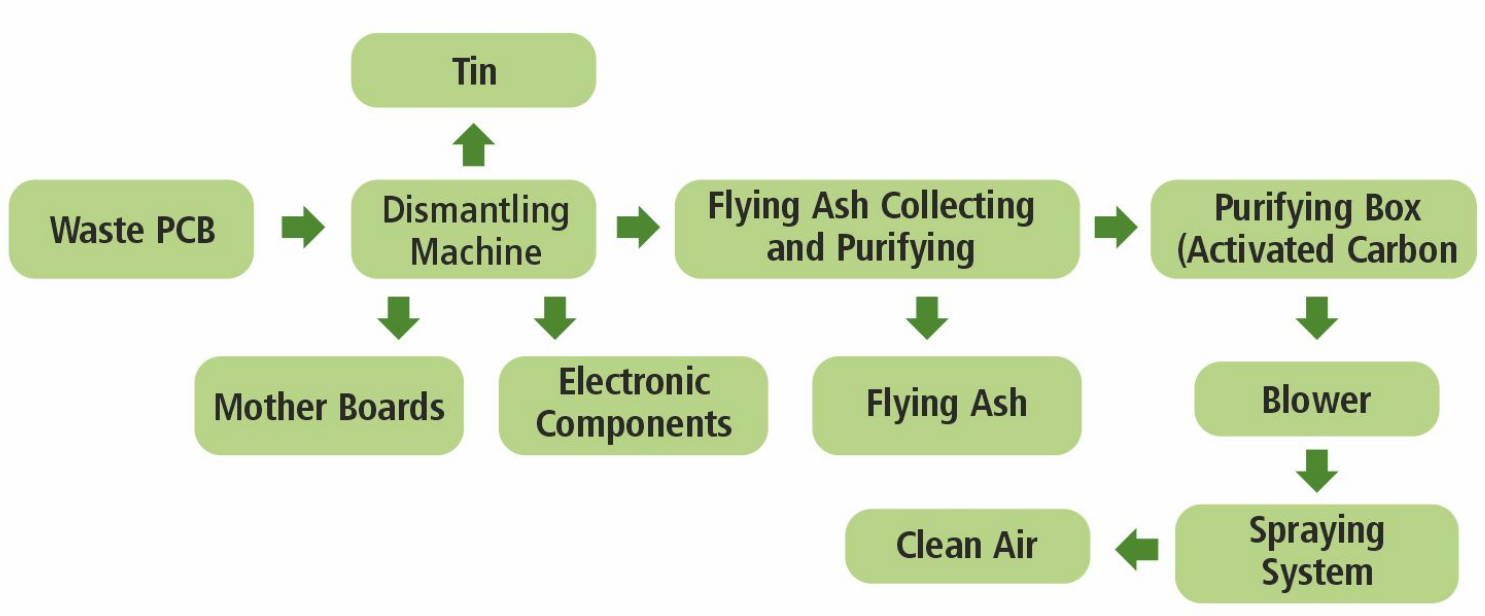

This Automatic dismantling machine is used to remove the electrical components from the waste PCB. Because the components are with different precious metals and some parts can be sell directly with a better price. And the mother boards after remove the components are easily to crush and separate the copper. It reduces the works of the next step, and make the precious metals can be recovered more.

| Model | Capacity (kg/h) | Power (kw) | Weight (kg) | Dimension (m) |

|---|---|---|---|---|

| LZCJ-200 | 200 | 4.85 | 450 | 1.67*0.97*1.4 |

| LZCJ-500 | 500 | 6.75 | 1100 | 2.1*1.27*1.74 |

| LZCJ-1000 | 1000 | 11 | 2180 | 2.74*1.83*2.43 |

APPLICATIONS

It used for waste circuit board motherboard, copper-clad boards, circuit boards, and the separation of leftover material of the mixed metal and nonmetal materials.

Waste PCB.

| Model | Power (kw) | Weight (ton) | Size (m) | Capacity (kg/h) |

|---|---|---|---|---|

| LZY-PCB150 | 65 | 7.5 | 12 x 6 x 5 | 100-150 |

| LZY-PCB300 | 102 | 15 | 20 x 5 x 5 | 200-300 |

| LZY-PCB500 | 134 | 20 | 25 x 6 x 5 | 400-500 |

| LZY-PCB1000 | 238 | 40 | 35 x 8 x 5 | 800-1000 |

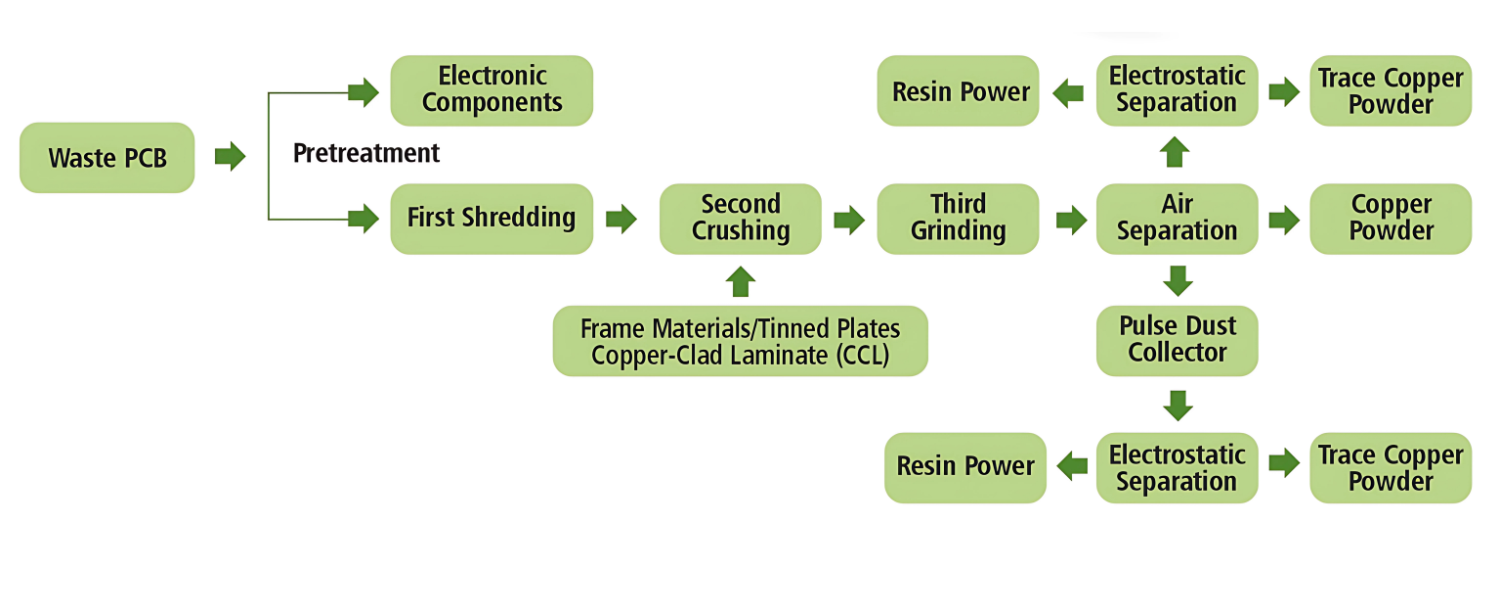

INTRODUCTION

The research of the recycling of waste Lithium-Ion battery is mainly focused on the recovery of the high-value cathode precious metals cobalt and lithium. Our company adopts an environmental-friendly physical separation process to realize efficient separation and recovery of waste lithium-ion batteries. The lithium-ion battery recycling production line is used for recycling the soft package battery, car battery, cell phone battery, shell battery, cylindrical battery, etc. The final products are black mass, aluminium granule, copper granule, plastic, iron shell and separator plastic.

| Technical Parameter | Value |

|---|---|

| Recovery rate of metallic aluminium | > 98% |

| Powder recovery rate | > 98% |

| Content of powder in metal aluminium | < 2% |

| Content of metallic aluminium in powder | < 2% |

| Black mass purity | > 99% |

| Copper purity | > 95% |

| Aluminium purity | > 95% |

Contain dust collection equipment and will not pollute the environment

| Model | Size | Power | Capacity |

|---|---|---|---|

| LDC-500 | 40m * 11m * 8m | 361 kw | 400-600 kg/h |

| LDC-1000 | 50m * 12m * 8m | 300 kw | 800-1200 kg/h |

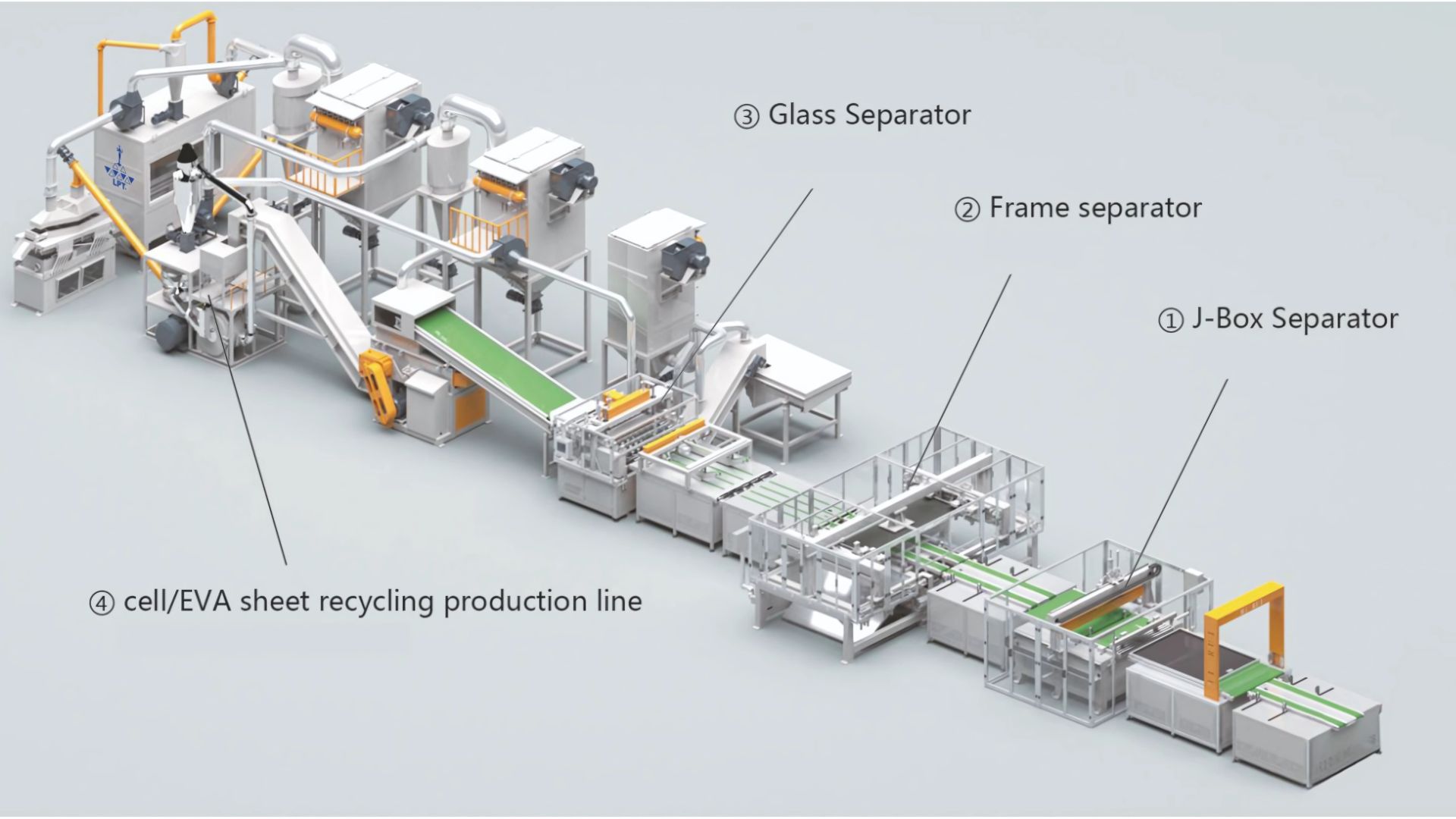

Solar Panels Recycling Plant

Components of solar panels includes high-quality glass, aluminium frames, polymers, silicon, copper and silver paste (for the printed conductors on each cell), all of which make up our equipment and can be successfully recycled. The recovery rate is above 95%. The figure below is the composition of our recycling line.

Foreword of Solar Panel

As normal, the service of one batch solar photovoltaic panels is about 25 years. With the development of emerging technologies and rapid product changes, the first batch of photovoltaic panels may be scrapped by 2025. Then there will be about 9.57 million tons scrap solar panels generated by the year of 2050. Therefore, recycling the waste photovoltaic panels will attract more and more attention.

Value of Solar Panel

Solar panels contain high content of glass, aluminium, adhesive sealant, silicon, silver and components, as well as rare metals such as cadmium and gallium, which have very good resource utilization value. RECYCLE equipment recycles waste photovoltaic panels through physical means such as automatic dismantling, crushing and sorting so as to achieve the purpose of recycling useful components.

Final Products

Aluminium frame is product of frame removing machine, the purity is 100% Glass granule and glass powder two products from glass remover, the purity is 99% The metal powder is copper powder and silver powder, the purity is 99% Silicon powder and a small amount of glass powder, the purity is 99% (Silicon about 80%) Powder plastic all from crusing & sorting part, the purity is 99%

Scrap Cable Recycling Line

It mainly used for processing waste communication cables, car cables, computer cables, telephone cables, home appliances wires and such these no oil pollution cables. The final Product is plastic granule and copper wire.

| Model | Capacity | Weight | Size (m) | Power |

|---|---|---|---|---|

| LZY-200 | 100-200 Kg/HR | 1800 kg | 1.8*1.8*2.5m | 25kw |

| LZY-300 | 200-300 Kg/HR | 3700 kg | 4.5*2.5*4.0m | 60kw |

| LZY-500 | 400-500 Kg/HR | 7500 kg | 6*3*4.0m | 85kw |

| LZY-800 | 600-800 Kg/HR | 10000 kg | 12*5*4.5m | 115kw |

| LZY-1000 | 800-1000 Kg/HR | 15000 kg | 20*10*4.5m | 185kw |

Double Shaft Shredder

Double-shaft shredder is suitable for the waste recycling requirements of various industries, such as: scrap metals, plastic, wood, household garbage, waste clothes, waste tires, pallets, electronic waste, cartons, etc.

| Model | LZY-D800 | LZY-D1000 | LZY-D1200 | LZY-D1500 | LZY-D2000 |

|---|---|---|---|---|---|

| Motor Power | 22*2Kw | 30*2Kw | 45*2Kw | 55*2Kw | 110*2Kw |

| Capacity | 1-1.5T/H | 1.5-2T/H | 3-4T/H | 4-5T/H | 10-15T/H |

| Blade Number | 20 pieces | 34 pieces | 24 pieces | 20 pieces | 20 pieces |

| Feed Hopper Size | 800*1200 mm | 1000*1500 mm | 1500*2000 mm | 2000*2500 mm | 2500*3000 mm |

| Model | LXR600S | LXR800S | LXR800S | LXR1200S |

|---|---|---|---|---|

| Power (kw) | 22 | 30 | 40 | 55 |

| Feeding mouth | 600*700 | 600*1100 | 800*1100 | 1500*1500 |

| Rotary blades (pcs) | 26+4 | 46+6 | 49+4 | 64+4 |

| Fixed blades (set) | 1 | 2 | 2 | 2 |

| Capacity (kg/h) | 600 | 800 | 1000 | 1000-1500 |

| Weight (kg) | 2800kg | 4000kg | 5500kg | 7000kg |

| Dimension (L*W*H mm) | 1700*1130*1780 | 1865*1420*1800 | 2470*1420*2000 | 3500*2300*2200 |

Single Shaft Shredder

Single shaft shredder properties as follows: strong, durable. It is suitable to recycle a variety of bulk solid materials, refractory materials, plastic containers and plastic barrels, plastic films, fibers, paper. Shredder particles can be small to 20mm according to different needs. We can provide all kinds of feed hopper; low speed rotary cutter in accordance with customer needs, which will be low noisy and energy saving.

Crusher

Crusher is used to crush various wastes into small pieces of granule materials. Reduce transportation costs and increase reprocessing speed. The discharge size of crusher is easy to adjust. Our crusher includes knife-type crushing and hammer-type crushing. Crushable materials include plastic, alloy, metals, etc. The knife crusher is suitable for crushing small-volume plastic. Hammer crushing is suitable for crushing various metal wastes, of which heavy hammer crushing is suitable for crushing large metal waste such as motor stators, compact metals, copper-aluminium radiators, etc.

Discover our full range of high-performance products, complete with specifications, use cases, and technical details. Download the brochure to learn more.

Enquire for

FREE TECHNICAL CONSULTATION

From machinery to maintenance, we provide expert guidance to boost efficiency.